http://www.alaska4x4network.com/showthread.php?t=16021

Anyway....

here goes.

They

have about 60 to

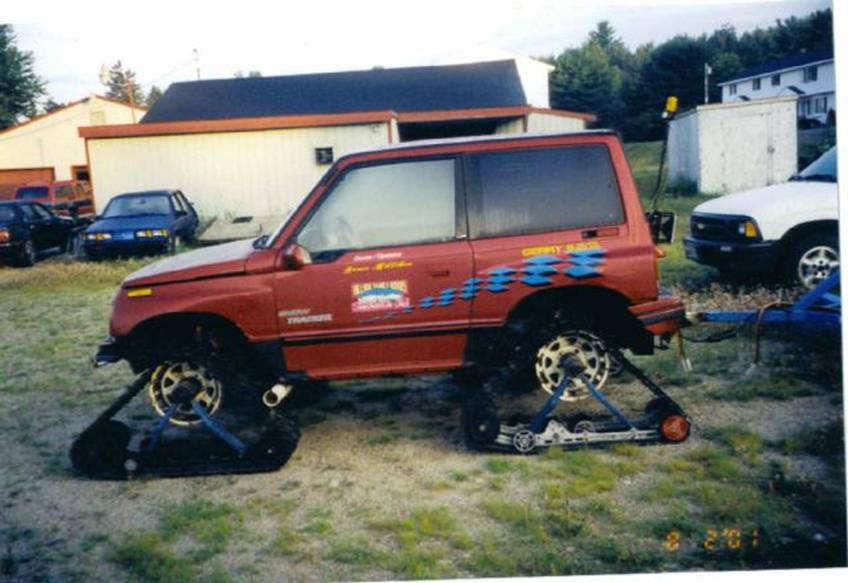

Speaking of vehicles, I am currently using a 1986 Grand Wagoneer. Why? Because

I have it and because I can. It has D44's front and rear, 2.72 gears in the

pumpkins, a fulltime 4wd t-case, (not quadra-trac) and 235/75r15 tires. Quite

the wheeler eh?

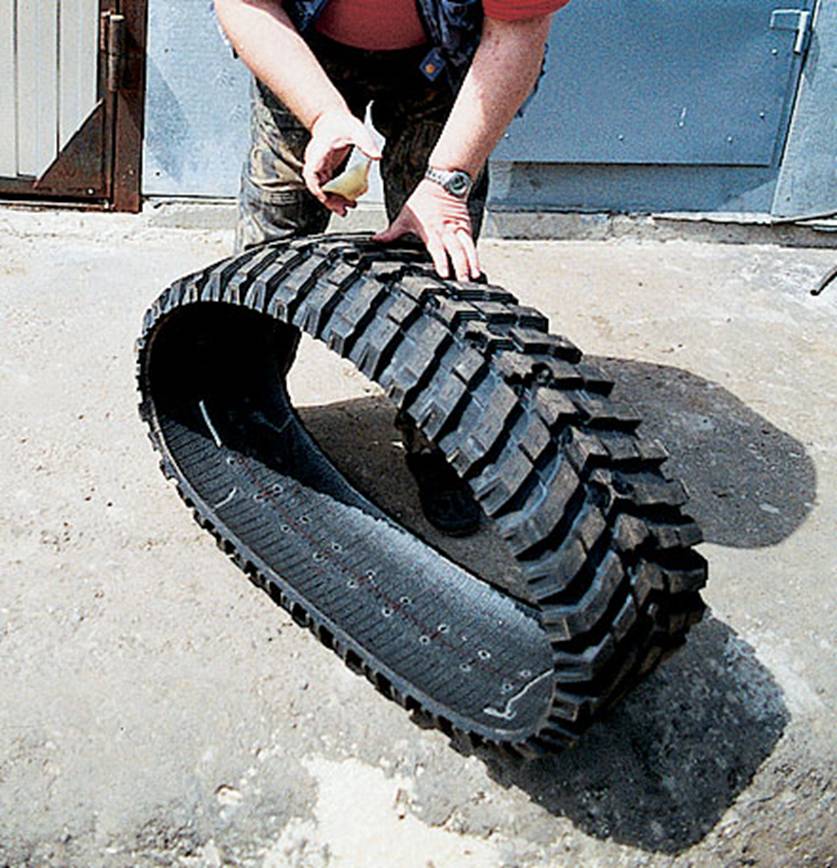

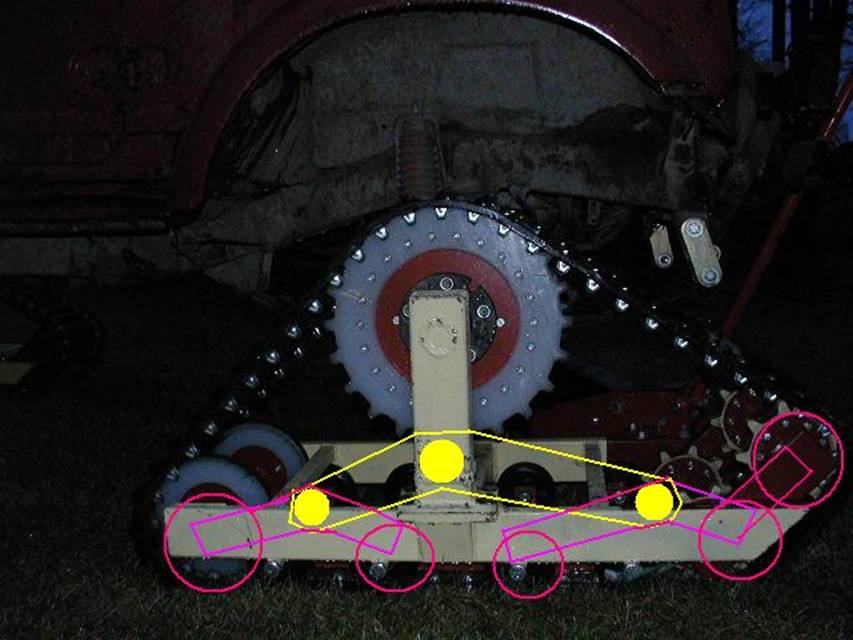

I had to re-inforce the outer edges of the tracks I purchased. These things are

at least 30 years old and are showing their age. I purchased

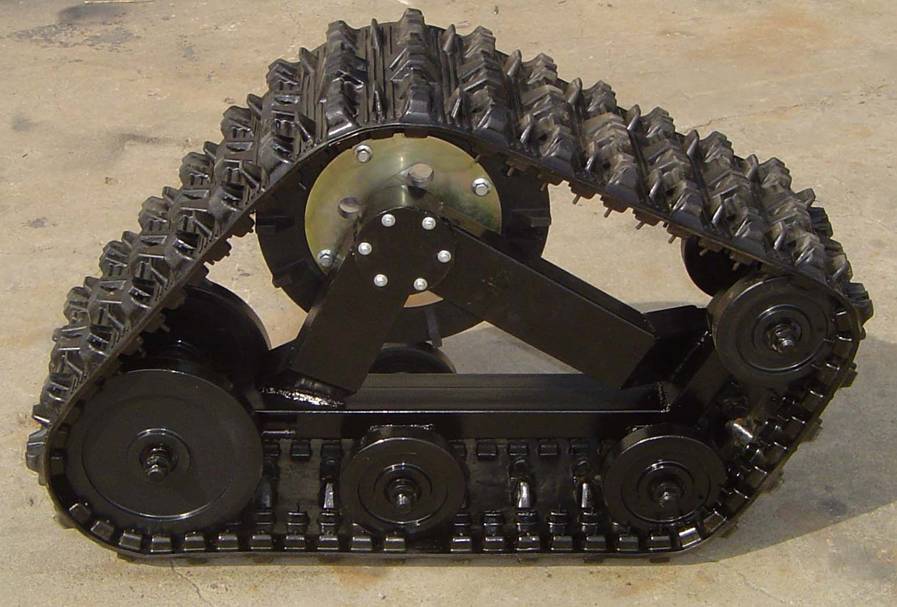

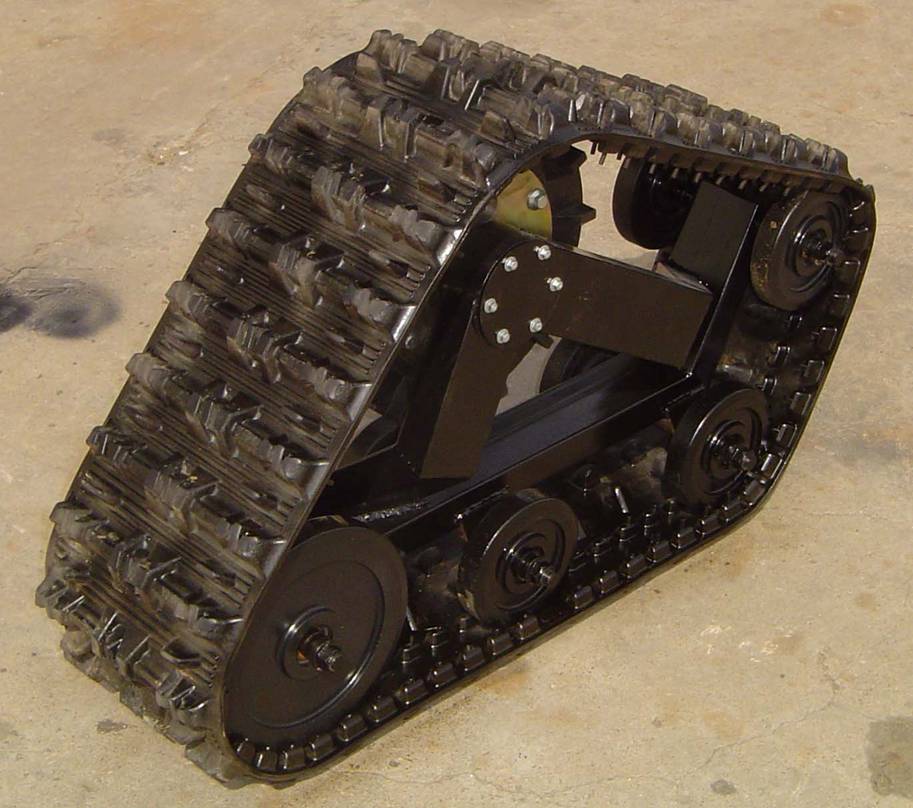

They have removable plates that bolt to the drive gears which allows you to

change bolt patterns. I can mount them on just about anything. However before I

can run them on an 8 lug rig I think I may need spacers to clear the brakes.

I weighed the Waggy at work the other day using airplane wheel scales. they

registered around 1000 pds on each front tire, and 800 poounds on each rear.

Not sure I trust them as they were at the begining of their measuring range. So

lets say 4750 pds. with me and gear. 4750 divided by 4080 = 1.16 pds per square

inch. Not bad. (Edit. Did some research on curb weights. G.Waggys were

somewhere around 4500-4750. So figure 5400 loaded. 5400 divided by 4080 =

How did they work? Great! Steering is an issue at times. Thats alot of material

to move across uneven terrain. I have an idea of a larger fullsize steering box

(bolt in) and modded pump. We'll try that first and if it doesn't do the trick

we'll do a ram assist. Also, the tendency of the track to want to lift in the

rear when up against a tall object showed up durring the test run. If you go up

against a large stump the track will want to torque over. Or if you go down

into a hole with an under cut bank it will do the same. In time I would like to

engineer in an angle on the front to help with this but for now I'm content.

They ride very smooth in snow. On frozen ground and ice they are rough. With no

cushion of air like inside a tire you get to feel all the little bumps a tire

would normally absorb. But I love the "point and shoot." These things

will take a bone stock Waggy places it has never even dreamed of going.

What a poser...

The main bodies and wheels etc. on these are all made from aluminum. They are

easy to move around, but not as easy as a large tire. Mounting takes some time

as you have to get the vehicle lifted up to the 24" level and then

position the track just right to slide over the wheel studs.

Getting one in position.

Lets roll!

Re: Wheel replacement tracks. Info.

A before "superman transformation" picture.

Ben lifting the jeep so Dan can put the track on.......

Ahhhhhh.........Remember the old days of 70's hot rods jacked up in the

rear............

Just

for comparisons sake...........Ben's on 35's......

Instant ground clearance.

heading into the trail

Being a moveable winch anchor

Got clearance?

INNE

FOTKI